Water is essential in kitchens, laboratories, bars and medical facilities. Yet when it is not properly controlled, it becomes one of the greatest risks to safety, hygiene and long-term durability. Poor drainage, standing water and uncontrolled splashes can damage cabinetry, weaken substrates and create avoidable cleaning challenges.

At GEC Anderson®, we specialise in stainless steel wet zone solutions that are engineered to manage water with absolute precision. From pressed recesses and shallow recesses to inline drainers and lipped edge profiles, our made-to-measure stainless steel worktops are designed to contain, direct and control water exactly where it needs to go.

If you are searching for stainless steel wet zones, integrated drainers, hygienic stainless steel worktops or water management solutions for kitchens and laboratories, this guide explains how correct configuration adds both functional value and professional finish to your project.

Tailored edge profiles to provide wet zone to sink

Why Wet Zone Design Matters

In high-use environments, water management is not a minor detail. It is a critical performance requirement.

In commercial kitchens, uncontrolled water can seep into cabinetry or flooring, leading to costly repairs. In bars and hospitality settings, surface pooling can create slip hazards and undermine the professional appearance of the space. In laboratories and medical facilities, effective containment is essential for hygiene and compliance.

Stainless steel wet zone design ensures:

- Water is directed towards drains and sink bowls

- Surrounding finishes remain protected

- Surfaces are easier to clean and maintain

- Long-term structural damage is avoided.

By integrating wet zone features into stainless steel worktops from the outset, projects achieve superior performance and durability.

Pressed Recesses Creating Defined Catchment Areas

A pressed recess is a flat, recessed area formed directly into the stainless steel worktop to create a defined wet zone or catchment area.

Key Features of Pressed Recesses

- Any size

- Any position within the worktop

- Variable corner radius (minimum 10 mm)

- Typically 4 mm deep

- Sink bowl(s) positioned within the recessed area.

This configuration ensures that any water spillage remains within a controlled boundary. Instead of spreading across the entire work surface, water is contained and guided back towards the sink.

Pressed recess stainless steel wet zones are particularly valuable in:

- Commercial kitchens with intensive washing activity

- Laboratory benches where liquids are regularly handled

- Medical preparation areas requiring controlled surfaces

- Bar counters where frequent rinsing occurs.

By pressing the recess directly into the stainless steel worktop, we eliminate joints and potential dirt traps. The result is a hygienic, continuous surface that performs as well as it looks.

Shallow Recesses for Enhanced Water Direction

Where more pronounced containment is required, a shallow recess offers an additional level of water control.

Features of Shallow Recess Stainless Steel Worktops:

- Made to any size

- Available with or without fall towards the bowl

- Minimum depth 10 mm

- Corner radius options of 0 mm, 10 mm or 15 mm.

The addition of a slope towards the sink bowl actively encourages water to return to the drainage point. This is particularly useful in laboratories, clinical settings and catering facilities where splashing is frequent and precision matters.

A shallow recess stainless steel wet zone is not merely a design detail. It is an engineered solution that protects cabinetry, substrates and adjacent finishes from long-term moisture exposure.

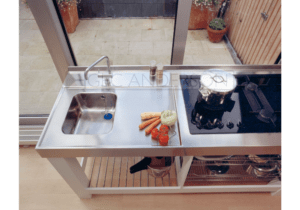

Inline Drainers for Sleek and Efficient Performance

Where a traditional drainer aesthetic is not desired, our inline drainer offers a modern, integrated alternative.

Inline Drainer Specification:

- Sloped area pressed into the worktop

- Positioned adjacent to the sink

- Length 400 mm

- Depth 400 mm

- Adjustable fall from 0 – 15 mm

- Available with Series A sinks.

An inline drainer stainless steel solution delivers efficient drainage while maintaining clean lines. The pressed slope ensures that water flows back into the sink without requiring separate components or surface-mounted accessories.

In hospitality environments, where visual impact is as important as practicality, the inline drainer provides a discreet yet highly functional water management feature.

Lipped Edge Profiles Protecting Surrounding Surfaces

Water control does not stop at the bowl or drainer. Edge detailing plays a critical role in preventing spillage from migrating beyond the worktop.

For worktops used in wet areas, we generally recommend lipped edge profiles, specifically edge 3 or edge 5.

The Role of Lipped Stainless Steel Edges

- Raised lip profile to prevent spillage

- Effective barrier against water migration

- Protects cabinetry and adjacent surfaces

- Enhances hygiene and ease of cleaning.

These lipped edge profiles form a perimeter defence, ensuring that water remains within the designated working area.

In kitchens, bars and laboratories, stainless steel lipped edges significantly reduce the risk of water penetrating into joints, walls or flooring.

Integrated Drainers and Bowl Configurations

Standard bowl and drainer combinations can be seamlessly integrated within GEC Anderson® stainless steel worksurfaces.

Unlike add-on components, our drainers are formed as part of the continuous stainless steel worktop. This means:

- No separate joints

- No crevices

- No dirt traps

- Improved hygiene

- Superior aesthetic consistency.

Integrated stainless steel drainers are ideal for commercial kitchens, catering facilities and medical preparation rooms where appearance and cleanliness are equally important.

BOSS Profile Enhancing Drainage and Practicality

For projects requiring an alternative surface treatment, the GEC Anderson® BOSS profile provides a practical and visually distinctive option.

BOSS Profile Benefits

- Raised dimple pattern at 55 mm centres

- Standard area 400 x 400 mm

- Facilitates drainage

- Suitable for placing hot pans.

The raised pattern allows water to flow between the profiles, reducing pooling while providing a robust working surface. In catering environments, this dual functionality is particularly valuable.

The BOSS profile stainless steel finish demonstrates how intelligent surface engineering can enhance both usability and longevity.

Protecting Surrounding Finishes and Substrates

One of the greatest advantages of stainless steel wet zone solutions is their ability to protect surrounding materials.

Timber cabinetry, plasterboard walls and decorative finishes can all suffer from prolonged moisture exposure. By integrating pressed recesses, shallow recesses, inline drainers and lipped edges into a single stainless steel system, we create a unified defence against water ingress.

In laboratories and medical settings, this protection is essential not only for durability but also for compliance with hygiene standards.

Made to Measure Precision for Professional Results

Every GEC Anderson® stainless steel worktop is made to measure, configured precisely to your project’s dimensions and requirements.

Wet zone elements can be positioned exactly where required, whether that is within an L-shaped configuration, a straight run or an irregular form.

This precision ensures:

- Seamless integration with cabinetry

- Accurate alignment with plumbing

- Efficient installation

- Professional finish.

Correct configuration at design stage prevents costly modifications on site and ensures long-term performance.

Applications Across Multiple Sectors

Our stainless steel wet zone and drainer solutions are trusted across demanding environments, including:

- Commercial kitchens and catering facilities

- Bars and hospitality venues

- Laboratories and research institutions

- Medical centres and clinics

- Education and training kitchens

- Industrial wash areas.

In each of these settings, effective water management is essential for safety, hygiene and longevity.

A Complete Integrated Stainless Steel Solution

Wet zones form part of a broader integrated stainless steel offering, including:

- Stainless steel worktops

- Fully integrated stainless steel sink bowls

- Stainless steel splashbacks and upstands

- Stainless steel cabinets and shelving

- Stainless steel sanitaryware.

By combining these elements into a cohesive specification, projects achieve unified appearance, consistent hygiene standards and enhanced durability.

Take Control of Water with Confidence

Managing water with precision is not an afterthought. It is a fundamental design decision that protects your investment and elevates professional standards.

GEC Anderson® stainless steel wet zones, pressed recesses, shallow recesses, inline drainers and lipped edge profiles are engineered to contain water effectively while delivering a clean, modern finish.

If your project demands reliable stainless steel water management solutions, buy online now from this website or contact us to discuss your requirements. Our team will help you configure a wet zone solution that protects your space and performs flawlessly for years to come.