STAINLESS STEEL

ABOUT GEC ANDERSON® STAINLESS STEEL

GEC Anderson® stainless steel possesses inherent attributes that combine to provide longevity, aseptic and maintenance free qualities that discerning end-users expect and require. These include:

• High durability with a resilience to heat, fire and sustained heavy use

• Totally hygienic composition

• Minimal maintenance

• Low lifetime costs

• 100% recyclability

Heightened awareness of food contamination issues, harmful emissions and toxins reinforce the trend towards use of stainless steel. However, it is the ability to form stainless steel into aesthetically desirable products with superior performance characteristics – visual and functional – that offers the key to using stainless steel successfully. In many instances, stainless steel is the only meaningful choice for serious long-term use.

BRUSHED SATIN FINISH

GEC Anderson® brushed satin stainless steel is practical and easy to maintain (unlike some highly polished stainless steels) and has a real lustre and shine that distinguishes it from the more commonly used ‘dull-polished’ and heavily grained finishes.

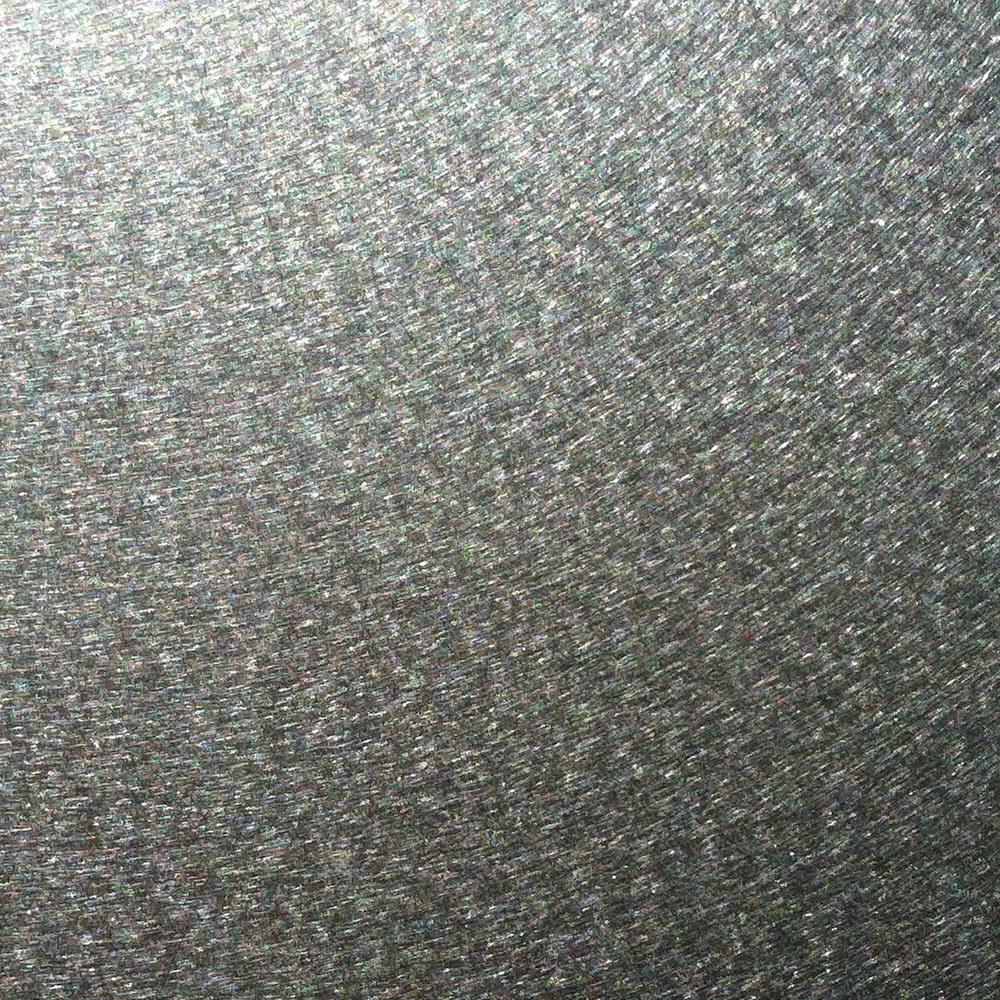

PATINA FINISH

A random micro-brushed pattern with matt appearance that is less susceptible to finger marks, scratching and general signs of wear and tear. Patina finish is applied to the worksurface and bowls.

GAUGE

1mm, 1.25mm, 1.5mm or 2mm. Normally, the selection of gauge is left to the expertise of our factory, depending on the size and nature of the product being manufactured.

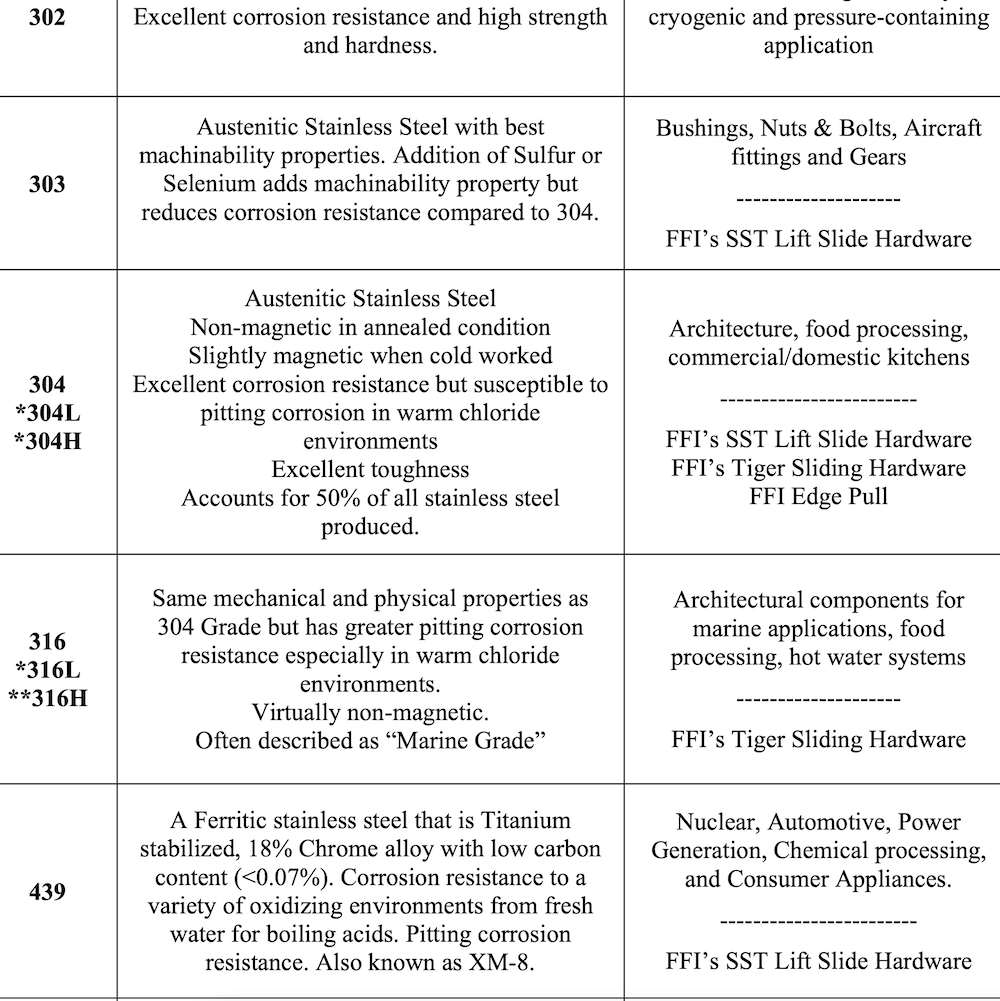

GRADE & COMPOSITION

Domestic grade stainless steel (EN 1.4301 otherwise known as 18/8 or AISI 304 grade or SIS2333) is generally used in our products. Acid resisting grade (EN 1.4401 otherwise known as 18/12 or AISI 316/319 or SIS2343) is used for equipment destined to be used in laboratories and certain special environments.

Stainless steel is the common name for the family of chromium-steel alloys containing a minimum of 12% chromium. A chromium-rich, ‘passive’ oxide film forms on the surface providing stainless steel with its unique anti-corrosive properties. This protective film will constantly ‘repair itself’ for example, when stainless steel is cut. The grade of stainless steel generally used in kitchens and bathrooms also contains at least 8% nickel and is known as austenitic stainless steel. The addition of nickel allows the stainless steel to become more ductile making it easy to work and form. Where higher resistance to corrosion is required (for example in laboratories), molybdenum is added.